Jinghua News

How to Achieve Ultra-Fine Grinding Below 5 Microns with a Jet Mill

Over the years, one question I hear again and again from customers is this: “Can your jet mill really achieve stable grinding below 5 microns?”

5 Signs It’s Time to Upgrade Your Jet Mill System

Over the years, I’ve visited hundreds of powder processing plants.

Many of them still run the same jet mill system they bought 10 or even 15 years ago…

How to Optimize Jet Mill and Air Classifier Integration for Maximum Efficiency

After years of working with powder processing customers, one pattern always stands out to me — most factories…

Choosing the Right Air Classifier for Your Jet Mill

In my years of working with powder processing customers around the world, one question comes up again and again…

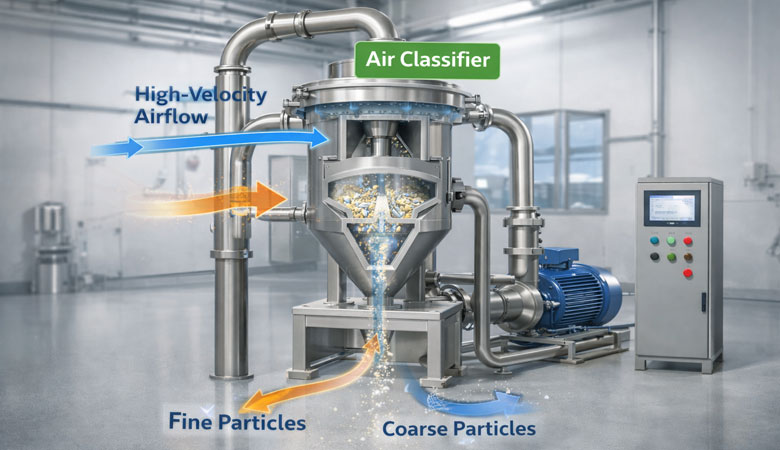

Air Classifier Design Principles: How to Improve Classification Efficiency

Whether in jet milling, mineral processing, or chemical powder production, the air classifier plays a decisive role in separating fine particles from coarse ones.

Avoiding Contamination in Jet Milling: Best Practices for High-Purity Powder Production

Jet milling is widely recognized for its clean, media-free grinding mechanism, which eliminates contamination risks typically associated with mechanical mills.

Energy Efficiency in Jet Milling Systems: How to Reduce Compressed Air Consumption

Jet milling is one of the most advanced and precise technologies for ultra-fine grinding in industries such as chemicals, ceramics, food…

The Role of Air Classifiers in Jet Milling: How Classification Improves Product Consistency

Jet milling has long been a reliable solution for ultra-fine grinding and micronization of powders across a wide range of industries…

Jet Milling in Food and Nutraceutical Powder Production: Preserving Nutrition and Improving Functional Performance

The global demand for functional foods and nutraceuticals has grown rapidly in recent years…