CXM Ultra-fine Roller Mill

Mills Powder Engineering - CXM Ultra-fine Roller Mill Manufacturer

Widely applied to Calcium carbonate, calcium oxide, calcium hydroxide, talc, bauxite, kaolin, diatomite, bentonite, graphite, limestone, calcite, activated carbon, marble, barite, gypsum, clay, chalk, mica, illite, pyrophyllite, vermiculite, sepiolite, attapulgite, rectorite, potassium alum stone, fluorite, phosphate rock, pitch coke, pyrolysis carbon black, ore, pumice, iron oxide red, iron oxide green, aluminum hydroxide, dyestuff, papermaking, flame retardants, building materials, the materials with Mohs hardness below 8, etc.

Working Principle:

The roller mill is equipped with three layers of grinding roller, when they rotate along with supports, the material is thrown to the grinding ring, and the material between the grinding roller and grinding ring is ground into powder, the ground materials enter into the classifying zone on the top together with ascending airflow, the coarse and fine powder are separated through the classifying wheel adjusted by the frequency conversion, the qualified powder is collected by the cyclone and dust collector, while the coarse powder would drop to grinding chamber to be ground again.

FEATURE:

1. Compared with Raymond mill or ball mill, the production efficiency is higher under the same dynamic conditions, lower operating cost.

2. Equipped Built-in classifying wheel to realize grinding and classifying at one time.

3. Compact structure and small occupation, easy to disassemble and clean.

4. Grinding is in closed system, low dust and noise, clean and environmentally friendly production process.

5. PLC control system, easy operation.

6. Can be connected with multi-stage classifiers to obtain products with multiple sizes at one time.

7. Particle sizes can be adjusted as needed.

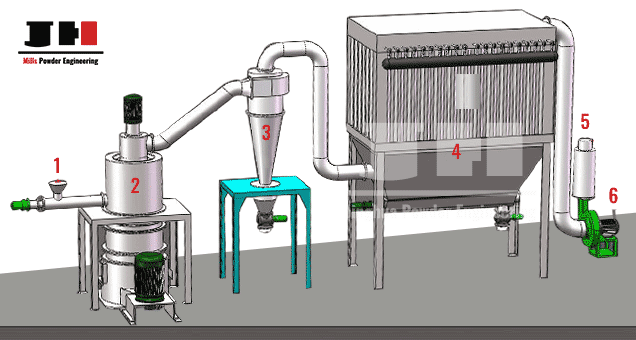

Working Flow Chart:

1. Feeding screw

2. Roller mill

3. Cyclone collector

4. Dust collector

5. Silencer

6. Draught fan

Technical Parameters:

| Type | CXM300 | CXM400 | CXM500 |

| Number of roller (pc) | 15 | 21 | 30 |

| Diameter of grinding ring (mm) | 720 | 900 | 1200 |

| Layers of grinding ring | 3 | 3 | 3 |

| Product size (μm) | 5-45 | 5-45 | 5-45 |

| Total power (kw) | 100 | 135 | 185 |

| Production capacity (for CaCO3) | 800kg/h | 1300kg/h | 1800kg/h |

| Power consumption/t | <90kw.h/t | ||